What is Oil Canning? Causes + Solutions For A Common Metal Roof Problem

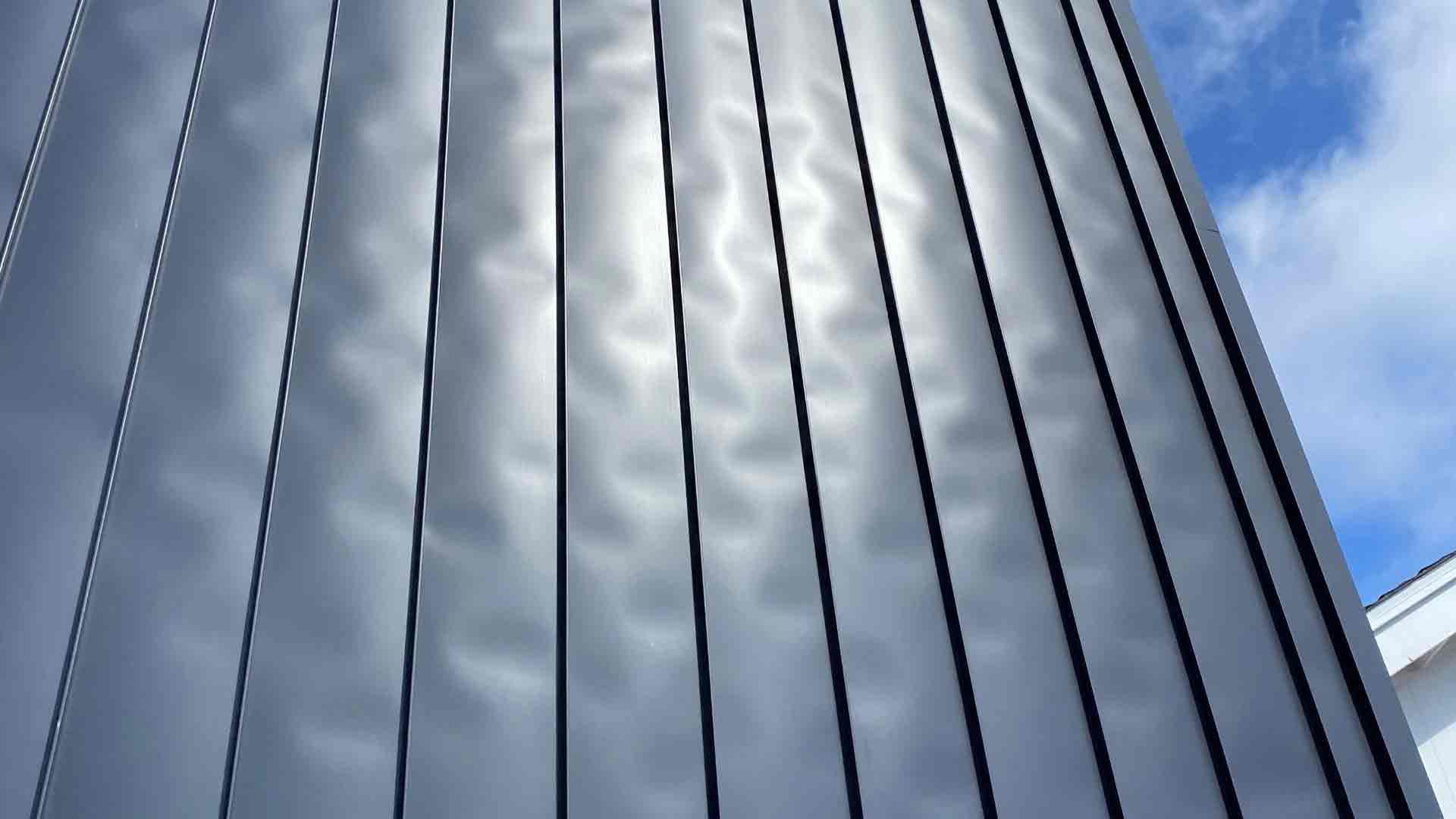

Have you ever seen a metal roof that looked like it was wrinkled? If you have, then you witnessed one of the biggest wonders of the metal roofing world, known as oil canning.

If any professional, such as an installer or manufacturer guarantees that your metal roofing or wall panel will never have oil canning, run fast and far in the other direction. Unfortunately, that's not true and you should look for a seller that won't make a false guarantee.

The truth is: oil canningwill occur in metal, as it's inherent in the product itself . However, there are measures you can take to help minimize and disguise its appearance.

At Western States Metal Roofing, we have been manufacturing metal roofing and metalsidingfor over 20 years. We are very knowledgeable about how metal responds to certain conditions that can cause the unwanted waviness.

In this article, we will discuss oil canning in terms of:

- What It is

- The Causes

- The Ways To Disguise It

- Prevention

What Is Oil Canning?

Oil canning is an inherent characteristic of light-gauge, cold-formed metal products with broad, flat areas. It is a moderate deformation that is cosmetic and not grounds for panel rejection.

It's an aesthetic concern that is observed as waves or wrinkles, in the flat areas of metal roofing and metal siding panels.

Sometimes also known as stress wrinkling, is solely an aesthetic issue and does not affect the functionality of a roof panel. However, it's presence is unwanted and hard to avoid.

What Causes Oil Canning On A Metal Roof?

- The Expansion and Contraction of Metal

- Overtightened Fasteners

- Uneven Substrate

- Underlayment That Is Not Flat

- Settling of a Structure

- Mishandling Metal Panels

- Roll forming

Pinpointing the cause is nearly impossible. There are so many different factors that can result in oil canning that can stem from factors during production, storage, handling or installation. We will go over some of the biggest causes below.

The Expansion And Contraction Of Metal

Metal naturally moves by thermal expansion. It expands in heat and contracts in cooler weather.

However, the panels are restricted from being able to move when they are double pinned at the edges. This stress on the metal's inability to expand and contract will result in an oil canning effect.

Overtightened Fasteners

A fastener that is overtightened is a common metal roofing installation error, and also leads to placing uneven stress on the panel.

Discover the right way to install fasteners on metal roofing by watching the video below:

Uneven Substrate

An uneven substrate, also called an out-of-plane substrate, will be reflected through the metal panels. The stress on the metal from not having a level or flat substrate will cause stress wrinkling.

Underlayment Not Being Flat

If the roof is not given a flat surface to lay on, it will not be able to lay flat itself either. Uneven underlayment will result in uneven stress put on the panel that can result in waves forming in different spots on the panels.

Settling Of A Structure

When metal siding is put on a building and then the building settles after installation, the panels are going to have oil canning. This is from essentially being squashed by the weight of the building coming down.

Mishandling Of Metal Panels

Panels need to be evenly supported when stored and transported. The panel should be supported every 12 feet so that the surface of the panel is always kept even. Allowing the panel to sink in the middle from not being supported can result in wrinkling.

Roll Forming

Even after metal is reshaped, it’s always trying to go back to its original form. Stress put on the metal during roll forming can cause oil canning from the metal moving and trying to become its original shape.

What Factors Best Disguise Oil Canning On A Metal Roof?

- Lighter Colored Panels

- Matte Finishes Instead of Glossy Finishes

- Panel Type

- Panel Width

- Roofs That Do Not Receive Direct Sunlight

Lighter Colored Panels

Waves are more obvious on darker colored panels. Using white or a lighter colored panel will help make it appear less obvious.

Matte Finishes

The stress wrinkles are more noticeable on glossy finishes. Using a panel in a low gloss finish or matte finish will help have a smoother appearance.

Panel Type

Consider the type of panel that is used. Oil canning is more visible on a standing seam panel than a corrugated panel because it has flat area.

Corrugated Panels

Corrugated panels that are already designed with corrugations, or waves/ribs, are the best at hiding visible waviness. Oil canning is most obvious on flat areas and corrugated panels either have limited flat surfaces or none at all.

Corten Panels

Corten panels arrive pre-rusted. Before the panel rusts, oil canning is easier to notice if it exists. However, once corten rusts any waviness that is present will be hard to see.

Panel Width

The wider the panel, the more likely visible oil canning is to appear.

Direct Sunlight Shows Oil Canning

Oil canning is most obvious in the afternoon when the sun is directly hitting the roof, exposing the shadows from the unwanted waves. It is more difficult to detect when a roof is surrounded by trees or does not receive direct sunlight. Having less direct sunlight also slows down the fading and chalking on painted panels.

How Can You Attempt To Minimize Oil Canning?

- Use A Heavier Gauge Metal

- Use A Corrugated, Not Flat Panel

- Stiffening Ribs And Striations

A Heavier Gauge Metal Helps Prevent Oil Canning

When deciding what gauge to use for your roof, keep in mind that thicker metal is better equipped to prevent issues as it's stronger and harder to bend. The lower the gauge number, the thicker the panel. Therefore, a 22-gauge panel is thicker and less likely to have wrinkles than a 26-gauge panel.

Standing seam is an example of a metal panel that has flat surfaces and is prone to oil canning. As a result, it's generally made with lower gauges to help prevent the appearance of stress wrinkling.

Corrugated Panels Decrease The Appearance Of Oil Canning

Metal needs somewhere to go when it expands and corrugations and corrugated panels help hide this movement.

⅞ Corrugated, PBR/ R-Panel, and Western Rib are the best panel choices as they do not have any flat surfaces.

Stiffening Ribs And Striations For Oil Canning Prevention

Oil canning can be decreased by the use of stiffening ribs or striations in your panels. Stiffening ribs, such as pencil ribs, are low-profile indentations added to the center of a panel with ribbed rollers. A striation is a pattern of linear grooves on the flat surface of the panel which runs parallel to the standing seam.

While both are used to disguise potential oil canning, striations are more effective in doing so than stiffening ribs because they're located throughout the entire panel. It is hard for it to be apparent on a panel with striations because the panel does not have any flat space.

Striations are more often recommended over stiffening ribs for maximum durability. Adding either striations or stiffening ribs does not increase the cost of the panels.

Remember that adding striations or stiffening ribs is not a guarantee that your panels will not have oil canning. However, if it occurs it will be less noticeable.

For more information on the types of stiffening ribs, we recommend reading:

What Is Standing Seam: Panel Systems And Stiffening Ribs

Should I Still Use Metal Roofing If There Is Oil Canning Present?

While you can take precautions to prevent an oil canning problem, there is no way to guarantee that it will not occur as it is inherent in metal. However, there are several factors, including product type and color, that can help disguise its presence.

Oil canning is merely a cosmetic issue that is not even always noticeable. It has no impact on the longevity, durability or performance of your roof. The potential for it should not impact a decision to invest in a roof that will give you 40-60 years of value.

Besides being one of the longest lasting roof materials, metal offers many other benefits.