Western Wave® Rigid Wall Panel: Pros, Cons, and Cost.

At Western States Metal Roofing (WSMR), we specialize in manufacturing metal siding in addition to roofing. We make several different metal siding and wall profiles to match every type of design and budget, including Western Wave®.

Western Wave® is our version of a rigid wall panel and is sold exclusively by WSMR.

In this article, we will discuss:

- What Is Western Wave®

- The Advantages of Western Wave®

- The Disadvantages of Western Wave®

- The Cost of Western Wave®

- Western Wave® Installation

What Are Rigid Wall Panels?

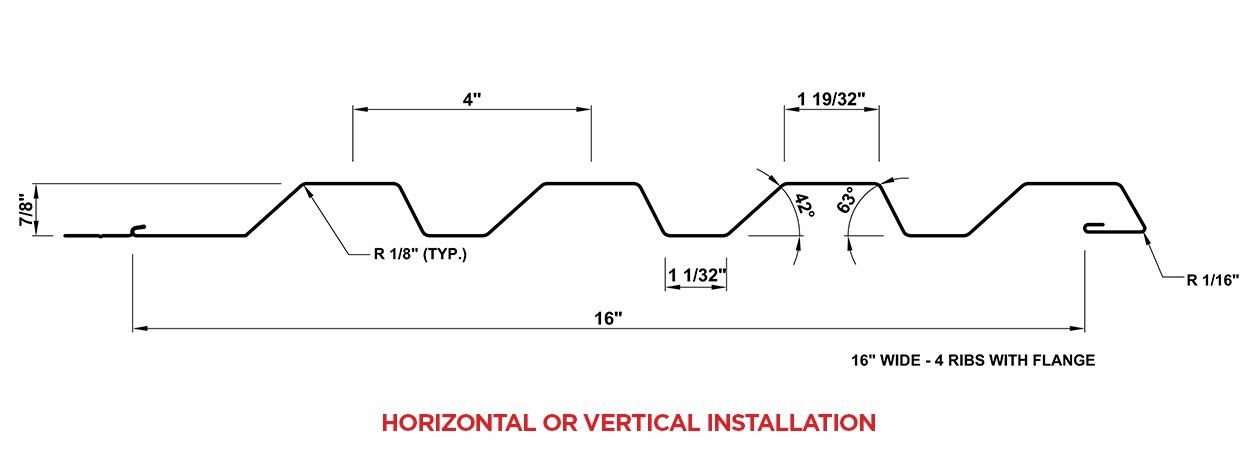

Rigid wall panels, such as Western Wave®, are structural metal siding panels with concealed fasteners that are used on residential and commercial buildings. They can be installed vertically or horizontally.

Each panel is 16” wide and consists of 4 ribs that are ⅞” deep. The ribs help make it a stronger panel. Western Wave® comes in a 24-gauge metal that adds to its durability.

Western Wave® also features a concealed fastening system. Having concealed fasteners not only increases the attractiveness of the product but also makes the panels more weathertight.

Our Western Wave® panels are available in hundreds of colors in a PVDF paint finish.

Advantages Of Rigid Wall Panels

- Low Maintenance

- Modern Appearance

- Concealed Fastener System

- Fire Resistant

- Dent Resistant

- Recyclable

Rigid Wall Panels Are Low Maintenance

Metal siding requires very little maintenance after installation. Periodically, you need to power wash Western Wave® metal wall panels as needed to keep the panels looking clean.

We also recommend occasional inspections of the panels just to ensure that a minor problem does not become a major problem.

Rigid Wall Panels Have A Modern Appearance

The ribs of Western Wave® panels are squared which gives off a modern appearance that is often desired. You also have hundreds of colors to choose from.

As we mentioned earlier, Western Wave® is a concealed fastener system. By the screws not being visible, it creates clean lines and a smooth appearance.

Rigid Walls Panels Have A Concealed Fastener System

- Western Wave® panels have a concealed fastener system which means the fasteners, or screws, are hidden and there are no penetrating holes on the surface of the siding. Western Wave has a much cleaner look than a standard old school metal siding panel such as ⅞” Corrugated, R-Panel, or Western Rib.

- This makes Western Wave® more resistant to leaks when compared to exposed fastener panels. The exposed fastener system leaves small gaps uncovered which can then allow water to get in and result in leaks.

Rigid Wall Panels Are Fire-Resistant

Metal is a non-combustible material. It is one of the safest siding materials as metal can help significantly reduce fire damage.

Western Wave® panels have a Class A fire rating which the highest rating a material can have. This means the panels will not spread flames.

Rigid Wall Panels Are Dent Resistant

Western Wave® panels have remarkable durability. The composition of metal provides protection from denting or scratching from weather elements or when hit with a high-impact object such as a soccer ball.

The ribs on a Western Wave® panel increases its strength, makes it harder to bend, and helps disguise any oil canning or other imperfections that may form on the panel. You will have much less oil canning on this type of panel when compared to a standard flush wall panel.

Western Wave® panels are made with a 24-gauge metal. Because this is a thicker gauge than most metal siding panels, you will have a more durable panel.

Rigid Wall Panels Are Eco-friendly

An extra advantage of using Western Wave® panels is the positive environmental impact caused by using metal. Metal, including steel, is the most recycled material in North America.

At the end of a Western Wave® panel’s lifecycle, the panel is 100% recyclable.

Disadvantages Of Rigid Wall Panels

- Not Compatible With Coastal Areas

- More Narrow Than Alternative Siding Panels

- Cost More Than Exposed Fastener Panels

Rigid Wall Panels Should Not Be Used In Coastal Areas

Western Wave® panels are manufactured with galvalume. Galvalume does not mix well with sea spray. Properties near the ocean, especially those that are within one mile from the ocean, are surrounded by a high amount of salt particles in the atmosphere. These areas, along with any areas with excessive moisture, can also sometimes be problematic for galvalume.

If your home or business is located in a coastal area, or an area that is subject to sea spray, frequent fog or other dampness should consider using an alternative siding.

Rigid Wall Panels Are More Narrow Than Alternative Siding Panels

Western Wave is 16” wide. By comparison, a box rib siding panel is 36” wide. It will take longer to install Western Wave when compared to a typical 36” wide panel as it has less coverage. If you have a very large project, you will have to install about twice as many panels.

Rigid Wall Panels Cost More Than Exposed Fastener Panels

The cost of Western Wave® panels is $3.00-$5.00 per square foot.

This makes them roughly 25%-35% more expensive than an exposed fastener siding panels such as Western Rib®. However, you are paying for better performance and a cleaner look.

As a concealed panel, Western Wave® is more weathertight, has fewer penetrations, and less likely to leak compared to an exposed fastener panel.

Installation of Western Wave® Metal Siding

At Western States Metal Roofing, we follow the industry standard way of installation. However, there are different install methods used throughout the country that are also correct. There are different ways to install metal siding.

The best way to avoid any errors is to hire an experienced contractor to do the installation.

Download Our Western Wave Guide For Vertical Installation

Download Our Western Wave Guide For Horizontal Installation

Why Should I Use Western Wave® Metal Siding?

Metal is a durable, low maintenance siding solution that will last you 40-60 years or longer. The modern, square appearance of Western Wave® panels has quickly made it favored among architects for new residential and commercial projects.

Western Wave panels are available in hundreds of colors, matte finishes, and even designer paint prints that are exclusive to Western States Metal Roofing. To visualize your home design ideas discover product colors, specifications, and more on our Western Wave product page.